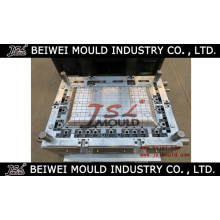

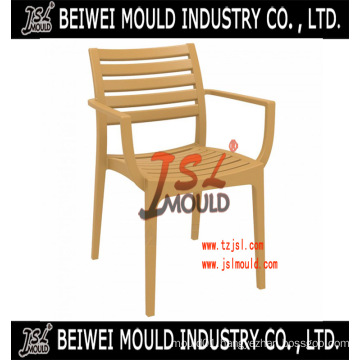

Outdoor Plastic Armed Chair Mould

Basic Info

Model No.: JSL-J16506

Product Description

Model NO.: JSL-J16506 Surface Finish Process: Polishing Plastic Material: PP Application: Furniture, Commodity, Home Use Design Software: UG Certification: ISO Customized: Customized Mould Quality Control: Professional QC Mould Standard: Dme Mould Cooling System: by Experienced Designer Mould Base: S50c Design Time: 7~10days Transport Package: High Quality Wooden Case Origin: Huangyan, Taizhou, China Shaping Mode: Injection Mould Mould Cavity: Single Cavity Process Combination Type: Single-Process Mode Runner: Hot Runner Installation: Fixed Standard: DME Size: According to Customers Requirement Mould Runner System: Hot or Cold Runner System Mould Design Software: Ug, Proe, Solidworks CAD, Ect Mould Operating Mode: Automatically by CNC Heat Treatment: Nitriding, etc Trademark: JSL MOULD Specification: DME HS Code: 8480719090 Injection Plastic Chair Mold

1. Provide 3D design

2. Mould steel/hardness: 718, 2738 HRC34-38, P20

3. OEM service

4. Mould life: 500, 00 to 1, 000, 000shots

Contact us if you need more details on Armed Chair Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Armed Chair Mould、Leisure Chair Moulds. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Provide 3D design

2. Mould steel/hardness: 718, 2738 HRC34-38, P20

3. OEM service

4. Mould life: 500, 00 to 1, 000, 000shots

| Product Name | Outdoor plastic armed Chair Mould |

| Product material | PP |

| Core& Cavity Steel | 2738 |

| Steel hardness: | HRC35-38 |

| Mould Standard | DME |

| Cavity Number | Single |

| Injection System | Side gate |

| Ejector System | Ejector pin |

| mould base | S50C |

| 45S | |

| Tooling lead time | 55DAYS |

| Mould life | 500, 000 SHOTS |

| Quality assurance | ISO9001 |

| Specification | According to client' s requirements |

| | |

| Our Advantage | 1. High quality |

| 2. Reasonable price | |

| 3. On time delivery | |

| 4. Good After-sale service | |

| 5. Strict quality control | |

| 6. All the mould are automotic. | |

| | |

| Offer you | In-time response on letters, telephone calls or fax |

| In-time supply the quotation and mould designs | |

| In-time communication on the technical points | |

| In-time sending pictures for the mould machining progress and mould finishing schedule | |

| In-time mould test and sample delivery | |

| In-time mould delivery. | |

| Plastic Injection Chair Mould | |

| 1. Samples/Drawing & Requirement from you | |

| 2. Mould design: we will Communicate& Exchange the opinion with you after you place order. | |

| 3. Material Purchase: Steel cutting and Mould base tooling. | |

| 4. Assembling. | |

| 5. Inspection of mould: following and controlling the tooling processing. | |

| 6. Mould testing: We will inform you the date. Than will send the sample' s inspection report& injection parameters with the sample to you! | |

| 7. Your instruction & confirmation for shipment. | |

| 8. Ready made mould before packing. | |

| | |

| For more information please contact us. | |

Product Categories : Chair / table Mould > Others Chair / table Mould

Other Products

Hot Products

Zhejiang Plastic mold supplier for standard size PVC pipe fitting mould in taizhouCheap Wholesale 2 cavity box mould2014 High Quality plastic mirror frame mouldmanufacturing household salable trash can mold,plastic waste bin mould for sale in factoryHousehold Product Product and Plastic Injection Mould Shaping Mode shopping basket mouldTaizhou mould factory for plastic injection crate basket mouldSemi Automatic Blow Moulding Machine for 3 and 5 gallon bottlesHot sale plastic edible oil cap mouldOEM custom high quality injection plastic mould factory in taizhouChina profession design manufacture plastic mould integrationOEM/ODM Custom Plastic Injection MouldHigh quality double deck 350kg plastic trolley cart2 Ton 2.5M Powered Operated Electric Hoisting Craneplastic moulding for electrical parts /plastic moulding for home appliances /China high quality plastic injection mold120L HDPE 3.5mm 7.3kgs outdoor mobile plastic wheelie bin storage with wheels and cover