OEM custom high quality injection plastic mould factory in taizhou

Basic Info

Model No.: plastic injection mould

Product Description

We are a member of Alibaba Trade Assurance which is a new service provided by Alibaba, safeguarding buyer's payment to suppliers to ensure suppliers fulfill their obligations regarding order delivery and product quality. We specialize in making plastic injection mould which covers a great range such as commodity mould ,household appliances mould, garden products mould and customized plastic parts. Our products are both excellent in quality and reasonable in price. Your satisfaction is guaranteed. We can provide some better suggestion on mold in order to make it cost effective. Such as selection of steel, usage of inserts, kinds of hot runner etc. With us your money in safe, your business in safe! plastic Injection Mould manufacturer Product Show Product pictures of Plastic Mould manufacturer

We are a member of Alibaba Trade Assurance which is a new service provided by Alibaba, safeguarding buyer's payment to suppliers to ensure suppliers fulfill their obligations regarding order delivery and product quality. We specialize in making plastic injection mould which covers a great range such as commodity mould ,household appliances mould, garden products mould and customized plastic parts. Our products are both excellent in quality and reasonable in price. Your satisfaction is guaranteed. We can provide some better suggestion on mold in order to make it cost effective. Such as selection of steel, usage of inserts, kinds of hot runner etc. With us your money in safe, your business in safe! plastic Injection Mould manufacturer Product Show Product pictures of Plastic Mould manufacturer

Product description of plastic mould manufacturer

Product description of plastic mould manufacturer | Option A: Level A quality(Highest Level Quality) | |

| Mould Base: | LKM,45# Steel |

| Core/Cavity: | S136+Becu |

| Slider/Insert: | S136 |

| Mould spare parts: | SKD |

| Hot Runner: | YUDO, Korea |

| Mould Life: | 800,000-1,000,000 shots |

| Cycle Time: | 40s |

| Option B: Level B quality(Middle Level Quality) | |

| Mould Base: | 45# Steel,self-made |

| Core/Cavity: | 718H |

| Slider/Insert: | 718H |

| Mould spare parts: | standard,China |

| Hot Runner: | Guangdong China |

| Mould Life: | 500,000-800,000 shots |

| Cycle Time: | 55s |

| Option C: Level C quality(Lowest Level Quality) | |

| Mould Base: | 45# Steel,self-made |

| Core/Cavity: | P20 |

| Slider/Insert: | P20 |

| Mould spare parts: | Standard China |

| Hot Runner: | Guangdong,China |

| Mould Life: | 300,000-500,000 shots |

| Cycle Time: | 60s |

2) Payment and delivery

2) Payment and delivery | Accepted Delivery Terms | FOB, CFR, CIF, EXW, Express Delivery |

| Accepted Payment Currency | USD, EUR, CNY |

| Accepted Payment Type | T/T, L/C, MoneyGram, PayPal, Western Union, Cash, Escrow |

| Nearest Port | Ningbo port,Shanghai port,Hangzhou port |

| Average Lead Time | 45 Day(s) |

| Minimum Order Value | >US$ 500 |

| Export Mode | Using an agent |

Why choose us We're assessed supplier of alibaba Benefits of doing business with an assessed supplier All assessed suppliers have been inspected onsite by a third party inspection company, giving you in-depth and authoritative information about suppliers including Assessment Reports, Verified Videos and Verified Main Products. China zhejiang Plastic Injection Chair Mould,plastic chair mold moulds,injection Chair Mould Manufacturer 1) UGO Previous moulds sample

Why choose us We're assessed supplier of alibaba Benefits of doing business with an assessed supplier All assessed suppliers have been inspected onsite by a third party inspection company, giving you in-depth and authoritative information about suppliers including Assessment Reports, Verified Videos and Verified Main Products. China zhejiang Plastic Injection Chair Mould,plastic chair mold moulds,injection Chair Mould Manufacturer 1) UGO Previous moulds sample

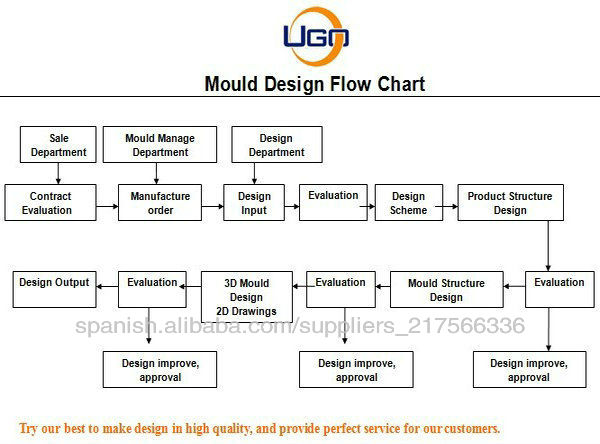

2) UGO mould advantages and advanced CNC machines 1.Professional in make all kinds injection plastic moulding. 2.High quality and competitive price. 3.Continuance service and technical support. 4.Rich experienced skilled workers. 5.Professional moulding designer. 7.High quality,reliability and long product life. 8.Mature,perfect and excellence 9.On-time delivery 10.We have passed the TUV certifcation. 3) UGO Chair Mould design flow chart

4) Order of plastic injection chair molds processing flow chart Step 1. Samples/drawing & requirements from you. Step 2. The sheet will be copied to our design department, tooling department to do the structure and feasibility analysis. Step 3. Before start mould design, the tooling schedule and processing sheet were done. Step 4. Mould design:at the same time we will communicate & exchange the opinions with you. Step 5. Material purchase:steel cutting and mould base tooling. Step 6. Inspection of mould:our processing manager are following and controlling the tooling processing. Step 7. Mould testing:we will inform you the date, then will send you the samples inspection report & injection parameters with the sample to you. Step 8. Ready to ship out. 5) Plastic mould design

4) Order of plastic injection chair molds processing flow chart Step 1. Samples/drawing & requirements from you. Step 2. The sheet will be copied to our design department, tooling department to do the structure and feasibility analysis. Step 3. Before start mould design, the tooling schedule and processing sheet were done. Step 4. Mould design:at the same time we will communicate & exchange the opinions with you. Step 5. Material purchase:steel cutting and mould base tooling. Step 6. Inspection of mould:our processing manager are following and controlling the tooling processing. Step 7. Mould testing:we will inform you the date, then will send you the samples inspection report & injection parameters with the sample to you. Step 8. Ready to ship out. 5) Plastic mould design  6) plastic mould making processing

6) plastic mould making processing

Processing | Time |

Prepare Steel | 5 days |

CNC Machining | 10 days |

Precision CNC Machining | 5 days |

Drill | 5 days |

Polishing | 3 days |

Assembling and Fitting | 5 days |

T1 mould test | 2 days |

Our market

Our market | Domestic Market | 30% |

| South Asia | 20% |

| Mid East | 15% |

| South America | 15% |

Southeast Asia | 7% |

| Africa | 5% |

| North America | 5% |

| Eastern Europe | 3% |

Mould for plastic buckets and pails

Mould for plastic buckets and pails

Mould for other Plastic Products

Contact

Contact  Contact us if you need more details on Plastic Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Injection Mould、Injection Plastic Mould. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Plastic Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Injection Mould、Injection Plastic Mould. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Plastic Bucket Mould

Premium Related Products

Other Products

Hot Products

Zhejiang Plastic mold supplier for standard size PVC pipe fitting mould in taizhouCheap Wholesale 2 cavity box mould2014 High Quality plastic mirror frame mouldmanufacturing household salable trash can mold,plastic waste bin mould for sale in factoryHousehold Product Product and Plastic Injection Mould Shaping Mode shopping basket mouldTaizhou mould factory for plastic injection crate basket mouldSemi Automatic Blow Moulding Machine for 3 and 5 gallon bottlesHot sale plastic edible oil cap mouldOEM custom high quality injection plastic mould factory in taizhouChina profession design manufacture plastic mould integrationOEM/ODM Custom Plastic Injection MouldHigh quality double deck 350kg plastic trolley cart2 Ton 2.5M Powered Operated Electric Hoisting Craneplastic moulding for electrical parts /plastic moulding for home appliances /China high quality plastic injection mold120L HDPE 3.5mm 7.3kgs outdoor mobile plastic wheelie bin storage with wheels and cover